Dust Extraction: What You Need to Know

Posted on: 12/07/2024, 00:00

Importance of Dust Extraction

According to a HSE report, Occupational Lung Disease Statistics in Great Britain 2023, approximately 12,000 people each year die of lung disease deaths related to dust exposure. Some of the deaths are directly attributed to past asbestos exposure.

Statistics published by the Labour Force Survey (LFS), the UK’s largest database of labour force statistical survey insights, uncovered that in the last three years there were:

• Approximately 19,000 new cases of lung disease amongst people employed in the previous year

• 43,000 new or longstanding cases of lung disease amongst people employed in the previous year

• 152,000 new or longstanding cases of lung disease amongst people who have ever been employed

It’s clear that exposure to dust has serious consequences, which is why understanding the different dust classifications and correct extraction methods, is paramount to safeguarding everyone’s health and well-being, whilst remaining compliant with all legislative regulations.

To learn more about dust extraction classifications, why workplace dust extraction is paramount, and how to choose the right V-TUF dust extractor for your purposes, keep reading below.

The Different Dust Classifications

There are three different dust classifications, and each requires specific extraction equipment to be safely removed from the workplace and prevent lung inhalation, ingestion, and absorption. The three dust classifications are:

Low Risk (L-Class)

L-Class classification presents a moderate risk when inhaled, ingested, or absorbed through the skin and is commonly associated with softwoods and Corian. The exposure limit is >1mg/m3 and successful extraction is only achieved with a dust extractor that captures 99% of dust with a grain size of under two microns.

Medium Risk (M-Class)

M-Class classification presents a medium risk when inhaled, ingested, or absorbed through the skin. It’s commonly associated with a wider range of materials, including repair compound and wood dust, filler and clear coats, cement, concrete, and tile cement dust. The exposure limit is >0.1mg/m3 and successful extraction is only achieved with a dust extractor that captures 99% of dust with a grain size of under two microns.

High Risk (H-Class)

H-Class classification presents a high risk when inhaled, ingested, or absorbed through the skin. It’s commonly associated with a wide range of materials, including mould spores, asbestos, mineral fibres, bitumen, and artificial mineral fibres, such as glass wool and includes carcinogenic or pathogenic particles. The exposure limit is >0.1mg/m3 and successful extraction is only achieved with a dust extractor that captures 99.995% of dust with a grain size of under one micron.

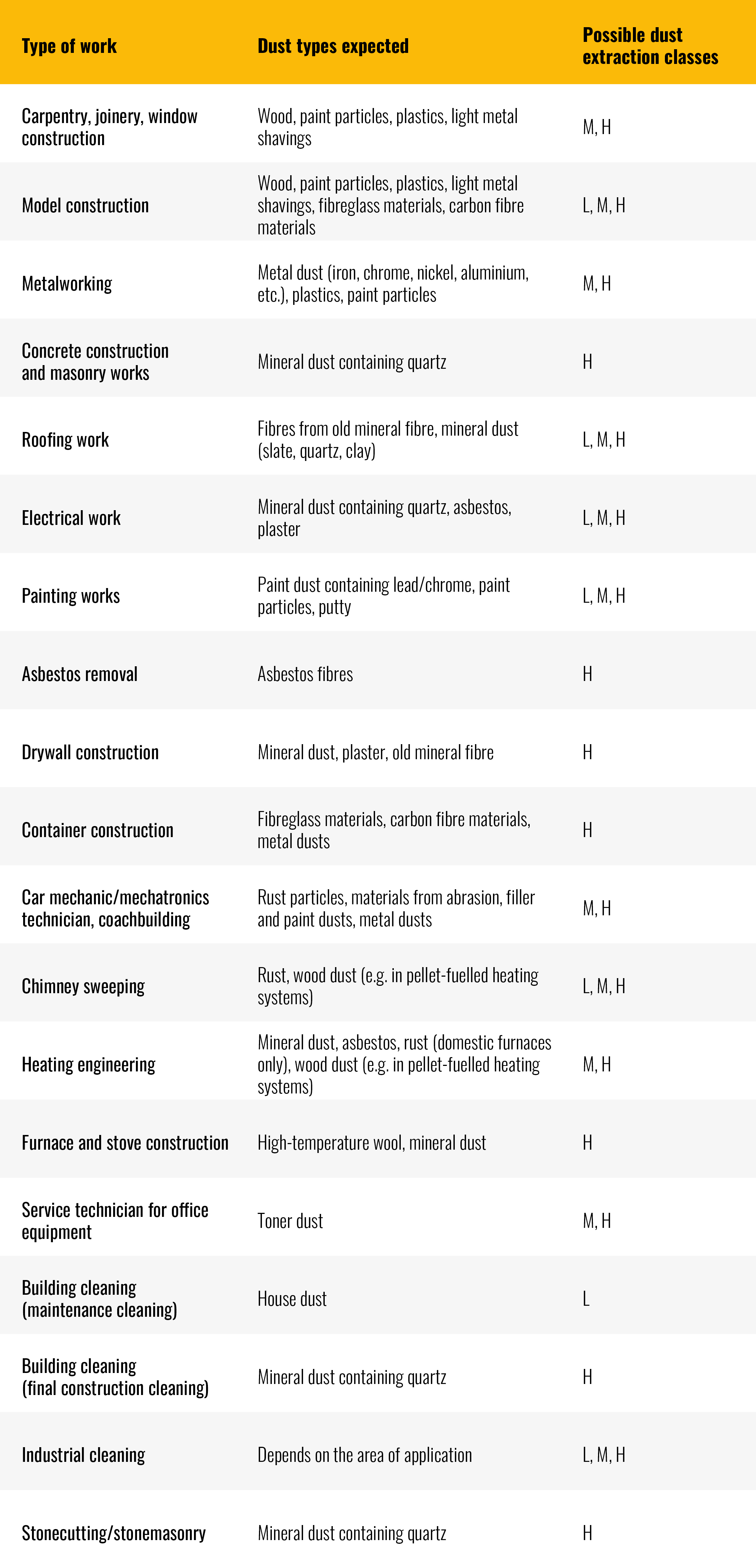

(See table below of dust types and where they are commonly found)

Reasons Why Workplace Dust Extraction Is Paramount

Monitoring workplace dust levels is so much more important than ticking health and safety compliance boxes. It’s critical to safeguarding the long-term health and well-being of everyone.

Not choosing the right dust extractor can have serious short and long-term, even deadly health ramifications for everyone in the working environment.

Below we’ve outlined what you’re risking when NOT employing efficient dust extraction.

Respiratory Concerns

Fine particles suspended in the air can be inhaled easily. This can result in respiratory tract irritation, coughing, and shortness of breath.

Skin Irritation

Dust exposure can cause skin irritation and allergies. This is notably true of people with allergies to specific types of dust, such as wood dust or latex. Symptoms can range from mild itching to dermatitis.

Material and Mechanical Contamination

Very fine, almost indistinguishable dust particles, especially those generated by the industrial process, can compromise the quality, safety, and integrity of products and raw materials.

Moreover, because dust absorbs the moisture in the air, it is a petri-dish for mould and corrosion. This may lead to reduced product lifespan and an increased need for repairs and replacement parts, ultimately resulting in greater overheads and decreased bottom line.

Fire and Explosion Risks

Certain types of dust are fire hazards. This can have catastrophic effects on workplaces. Combustible wood, coal, and metal dusts can easily and quickly accumulate in workplace environments.

If not extracted comprehensively with a dust extractor capable of extracting L, M, and more importantly, H-Class dust, fire and explosions are a clear threat under the right circumstances.

Fine particles of combustible dust can become airborne, especially when sanding, grinding, or cutting materials. Electrical sparks, heat, or even electrical equipment can ignite the particles, causing a fire.

Permanent Damage to Respiratory Health

Prolonged exposure to airborne dust and particles, especially silica, can lead to severe, respiratory health illnesses, including COPD (chronic obstructive pulmonary disease), lung cancer, and silicosis (a debilitating lung disease caused by the inhalation of crystalline silica particles.

Silica dust is commonly found in construction, mining, and manufacturing. Concrete, stone, and brick all contain silica. Cutting, grinding, or drilling materials that contain silica releases fine dust particles. When inhaled, absorbed, or ingested, these dust particles can cause irreversible damage to lungs.

Employer’s Legal Responsibilities

There are several key government guidelines that aim to safeguard people by minimising the amount of dust in the workplace. The most significant legislation for employers to be aware of are:

• The Health and Safety at Work Act 1974

• The Coal Mines (Respiratory Dust) Regulations 1975

• The Control of Substances Hazardous to Health Regulations 1988

In addition to the 19,000 new cases of lung disease attributed to dust in the workplace, statistics have uncovered that there are also 17,000 new cases of lung or breathing problems that can be directly linked to dust inhalation, and skin absorption.

Employers are legally responsible for maintaining a safe workplace for all employees. Not providing a safe environment for employees can have serious legal and financial consequences for employers. Using a dust extractor with the classification required to proficiently remove all dust threats will help to safeguard employee health– and your business.

How to Choose the Right Dust Extractor

Choosing the right dust extractor depends on its purpose. This is the only way that you can be assured of buying the right product. Below are a handful of considerations to inform your decision.

The level of filtration needed: L-Class, M-Class, and H-Class dust extractors feature ascending levels of dust extraction, helping you to decide which is best suited to your purpose.

Power source: You have the option of either 110v or 240v corded and cordless dust extractors. Mains powered dust extractors typically have greater power efficiency than cordless dust extractors.

Power take-off point: with a power take-off point operators need only use a single plug socket for the dust extractor, provided that the wattage of the dust extractor matches the power of the plug socket’s capabilities.

Auto on/off: various cordless M-Class and H-Class dust extractors have a function that automatically runs with the machine in use. They are connected to the power tool using Bluetooth and will recognise when the machine is in use.

Capacity: dust extractors have varying capacity sizes. V-TUF’s range offers anywhere from 15L to 80L. Cordless dust extractors feature smaller capacity sizes because the unit must accommodate the battery.

Wet or dry pickup: some M-Class and H-Class dust extractors provide both wet and dry pickup making them ideal for specific environments.

Auto Clean: it’s not uncommon for dust extractors to be sold with an auto clean function to clean the filters. They’re usually designed with two filters operating in tandem, with one filter cleaning the surface and one filter removing harmful substances.

V-TUF Will Help Protect Your Workplace Against Dust Threats

Employers need the right dust extractor to ensure that your workplace is compliant and safeguards the health and well-being of everyone.

V-TUF stocks a range of M and H-Class fit-for-purpose dust extractors and vacuum attachments that will protect everyone across all commercial environments from all forms of dust.

Click the link here to view our dust extraction range, or get in touch with us today to learn more.